We've been working on our wood spoons and utensils for several years to try and get them perfect. Why? Because a great wood spoon represents Field Company values just about as well as our cast iron pans: they're made of natural materials, they don't burn or melt, they last a lifetime, you use them every day, and they acquire a handsome character and patina that only makes them more valuable as they age.

And most importantly: when we looked around, we didn't see any widely available wood utensils that were doing it right.

The Lightbulb Moment

We fell into wooden spoons in a similar way we fell into cast iron. With cast iron cookware, the lightbulb moment was seeing and feeling the difference between great vintage cast iron and modern, cheap cast iron. With wood spoons, Stephen, one of the Field founders started to carve them by hand as a hobby. And we noticed that great hand carved spoons were quite different from commercially available spoons. And most importantly: when we looked around, we didn't see any widely available wood utensils that were doing it right.

There's a fundamental tension between manufacturing—where you are trying to make everything the same—and wood as a material. With wood, every piece has different grains, knots, and properties. When we make products at Field, we aim to embrace variability and uniqueness while bringing craft and human judgment to natural materials and modern technologies.

Designing the Best Spoons

You can get a very functional, affordable wooden spoon. But we wanted to make the best wooden spoon, using the best wood, consistently with local manufacturers in America.

Our research and development phase started with finding what we thought was best. Which led us to Emmet van Driesche—a talented spoon carver who's made thousands of spoons by hand and publishes Spoonasaurus. We were drawn to designs that were part spoon and part spatula. And we knew that a thicker handle felt much better in the hand.

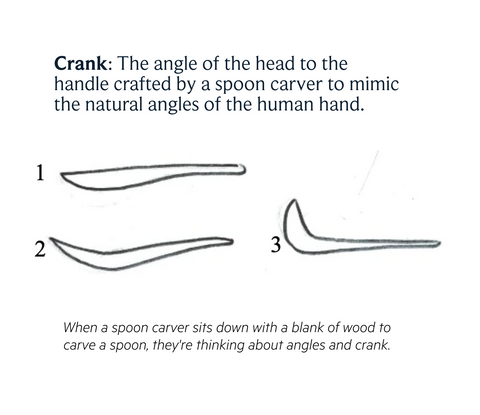

One component that we didn't want to compromise on was crank—the angle of the head relative to the handle. This is a feature often seen in hand carved spoons and dramatically increases the ease and versatility of use. Other manufactured wood utensils are made flat because it's cheaper and easier to make them that way. We believe that if you're going to make a tool you use every day for decades, make it right.

When we make products at Field, we aim to embrace variability and uniqueness while bringing craft and human judgment to natural materials and modern technologies.

The Shapes

We tried hundreds of samples over several years—some hand carved and some machine made. We found ourselves gravitating to three shapes in our own cooking: a spoon, a spatula, and a spoontula.

The spoon is self-explanatory and does what spoons do best: stir, taste, scoop, and serve.

The spatula has the sharpest edge for getting underneath things. We use it for frying, especially scraping up the fond with foods that caramelize a bit like onions and mushrooms. It’s also fantastic for scrambled eggs. The head shape is the right size that blends maneuverability with scoopability.

The spoontula is a hybrid—and one of the Field team's favorites. It provides some edge to scrape up food from a pan’s surface, but also a bit of a bowl so your food does not fall out.

We’re always using a couple when we cook and a couple serving, so for us, having a set of 3 was imperative.

Manufacturing the Best Spoons

We choose cherry as our wood. It’s a solid, tight-grained North American hardwood that is smooth, durable and well-suited to a kitchen environment. We love it’s warm tones and the fact that—like cast iron—it develops a nice patina over time.

The quartersawn cherry we use comes from a local sawmill about 50 miles away from the workshop where these are produced in Vermont. This shop and the folks who run it share our commitment to quality and worked tirelessly with us to execute our product vision without compromise.

Getting the crank we wanted was a challenge. Initially, we thought we could save cost by steam bending the wood to the appropriate angle. Unfortunately, we realized we had issues when we left a steamed spoon over a pot of boiling pasta water and the crank disappeared (also known as springback). Through many iterations we were eventually able to hit our design using larger wood blanks of quartersawn cherry, which also improved the strength and longevity of the tool.

We are passionate makers who study and learn from the past in order to make the best versions that we can of our products—whether a cast iron pan, a leather mitt, or a wooden spoon—and to make these products in America. If you are a customer of any of our products, thank you. We love hearing feedback and answering questions, please drop us a note anytime hello@fieldcompany.com.